#big bags

Explore tagged Tumblr posts

Text

#autumn fashion#girly fashion#girly#mori girl#dress#cardigan#big bags#bags#vintage fashion#vintage#aesthetic#pastel colors#floral#autumn#street fashion#street style#girl fashion#youth#vintage jewelry#jewelry#knitting

53 notes

·

View notes

Text

Dries Van Noten Fall 2010

18 notes

·

View notes

Text

#october#autumn#autmn aesthetic#november#september#uggs#big bags#vouge#vintage cars#old tumblr#vintage#2000s nostalgia#2010s tumblr#2010s nostalgia#rainyday#warm#dark red#boots

11 notes

·

View notes

Text

Beautiful colors combinations!!

3 notes

·

View notes

Text

Yenesai SS25 shot at Paris Fashionweek

#yenesai#paris fashion week#paris fashion show#grey outfit#catsuit#baglover#big bags#styledujour#street style#fashion photography#sketchonista#hypebaestyle#street fashion#ootdstyle#ootd#ootdinspiration#ootdfashion#outfit#fit check#outfit inspiration#outfit inspo#swag style#fashion tag#fashion trends#fashion tips#fashion tumblr#style guide#dailystyle#styleinspo#style inspiration

3 notes

·

View notes

Text

I look back at how many items Link, Hero of Legend has. Because of how many Zelda games he's appeared.

0 notes

Text

This Duffel Bag is perfect for coffee lovers on the go. With its durable polyester fabric and multiple compartments, it provides easy access and safe storing for all your essentials. The adjustable shoulder strap and carrying handles make it convenient and comfortable to carry. This bag is ideal for adults looking for a stylish and functional accessory for travel, gym, or everyday use, especially during holidays and vacations.

Product features

- Zipper closure for easy access

- Multiple compartments for organized storage

- Adjustable shoulder strap for comfortable carrying

- Durable polyester fabric

- Ideal for adults

Care instructions

- Dryclean

0 notes

Text

Flexible Intermediate Bulk Container (FIBC): A Comprehensive Guide

Modern industrial packaging depends critically on flexible intermediate bulk containers (FIBCs), sometimes known as bulk bags, huge bags, or jumbo bags. These adaptable containers are made especially to safely and effectively store and move big goods. Applied in sectors including food, chemicals, chemicals, and building, FIBCs have transformed bulk handling operations by providing a dependable and reasonably priced packing option.

FIBCs: what are they?

Made of spun polypropylene fabric, FIBCs are big, flexible bags. Grains, sand, fertilisers, chemicals, and plastics are among the dry, flowable goods they are meant to contain and move. Depending on their construction and design, these containers can hold capacities between 500 kg and 2,000 kg or more.

Characteristics of FIBCs

Made from high-strength polypropylene, FIBCs are structural integrity-preserving yet heavy load handling tool.

FIBCs can be tailored to fit certain uses by means of size, form, and feature set including spouts, loops, and liners.

FIBCs, lightweight and reusable, cut storage and transportation expenses as compared to rigid containers.

Many FIBCs can be designed with sustainable materials and are recyclable.

FIBCs, with lifting loops, let forklifts or cranes be used for simple handling.

Various FIBC forms

FIBCs are arranged according to their application and construction:

Standard bags devoid of any static protection, type A FIBCs are used for non-flammable products.

Type B FIBCs are designed for dry, combustible materials, they provide only modest defence against static.

Perfect for combustible surroundings, Type C FIBCs are built with conductive materials and grounding systems.

Type D FIBCs are Designed for delicate materials, provide static dissipation free of grounding.

Typical uses for FIBCs

Agriculture: Agricultural transportation covers fertilisers, seeds, and grains.

Construction: Perfect for sand, gravel, and cement is construction.

Chemical Industry: Move and safely stores powdered resins and chemicals.

Food Industry: Appropriate for bulk food materials including sugar and flour.

Recycling: Managers garbage products and recyclables effectively.

Benefits of FIBCs

Fit for a range of products and sectors.

Stackable and collapsing helps to save storage space.

Reusable designs help to lower the packing waste.

Enhanced safety lowers the chance of contamination and spillage.

Considerations for FIBC Selection

Material and Construction: Choose according on weight, flowability, and sensitivity of the product.

Safety Requirements: Verify adherence to safety norms particular to your sector.

Customising: Select designs fit for your operational requirements.

Liners and Coatings: Use liners for products vulnerable to moisture or contamination.

FIBCs: Novel ideas

Anti-static compounds, UV-resistant coatings, and biodegradable choices are among recent developments in FIBC manufacture. These developments answer contemporary issues including improved safety and environmental sustainability.

Eventually

A must-have tool for bulk material handling, FIBCs provide unparalleled adaptability, efficiency, and safety. Investing in premium FIBCs allows companies to maximise their operations, lower expenses, and help to create a more sustainable future. FIBCs offer a consistent answer for your packaging needs whether you handle chemicals, building supplies, or agricultural items.

0 notes

Text

Hiandra Martinez with wonderful bag add for Gucci ( IG hiandramartinez ).

Photo by Anthony Seklaoui

#italian fashion#italian art#high fashion#big bags#leather bag#gucci fashion#gucci#italian charm#dominican republic#dominican girl#república dominicana#italian photography#blue jeans

0 notes

Text

Latest Innovations in Big Bags for Bulk Storage

The packaging industry has evolved over these years, and Big Bags have become a major choice for bulk storage and transportation. Flexible or Bulk Bags are the alternative names for them and are used in agriculture, construction, chemicals, and food packaging. As a result of the clients' increased demand, manufacturers have been tirelessly improving their product's performance, durability, and sustainability. So what are the newest trends and technologies that development of the Big Bag industry are dependent on?

1. Enhanced Material Strength and Durability

The updated capacity of the big bags is provided by the polypropylene (PP) materials which have been used for these synthetic bags and popup bags. Such materials are designed for lifting mighty loads, which makes them ideal for the storage and transportation of bulk commodities such as grains, fertilizers, and construction materials.

Manufacturing companies are the ones using a combination of techniques to include Polypropylene in the correct manner that will not let the master bags fill join with the moisture, ultraviolet rays, or physical damage, hence the bags will still be durable, and also will protect the goods from physical damage and little moisture during the storage and transportation.

2. Sustainable and Eco-Friendly Designs

The packaging industry propelled sustainability on top of the agenda. The peer-to-peer technologies have opened the door to the use of recycled materials and biodegradable additives in PP Woven Bags, which have in turn lowered the impact of bulk packaging on our environment.

Plenty of manufacturers with polypropylene bags are working on creating truly bulk bags that can be used for a few times and later can be recycled. The switch to more ecological solutions is beneficial for companies and the environment because it results in less waste and a more efficient use of resources.

3. Customization for Industry-Specific Needs

Customization stands out most among Big Bags. The manufacturers have now come up with customized solutions to meet the specific requirements of various industries, which they now offer to their customers. For instance:

Food Industry: Bags that contain food-grade liners to ensure hygiene and safety.

Construction: Bags that are very tough and are made to carry the materials such as sand and gravel.

Agriculture: Ventilated PP Woven Bags is an example of Breathable bags used for stocking web shops and seed banks. Advantages take account of the airflow which avoids that products turn bad. This kind of bag let's air and moisture pass through and avoids problems associated with condensation.

The size, shape, and the printing of the bags are also included in the scene of customization. This way, the companies are able to add their logos and information about their products even to the bags, hence, they are able to promote their marketing.

4. Improved Safety Features

A number of actions have been taken to improve safety for Bulk Bags, particularly in the industries involved in dangerous or heavy materials. Recent innovations include:

Antistatic Big Bags: These bags are indispensable in industries that deal with combustible materials because they are intended to reduce the collection of the static electricity that could result in an explosion.

UN-Certified Bags: What this means is, the bags have been tested and approved for transporting dangerous goods and are thereby guaranteed to be in health and safety compliance with the international standards.

Reinforced Lifting Loops: Because of the improved loop designs, the possibilities of lifting accidents have been much minimized and the operation and mobility of transportation have become more improved and efficient.

5. Advanced Coatings and Liners

The introduction of custom features these days has been the reason for a huge number of options available in Big Bags with results that suit almost everyone. By using such materials with the layer of coatings and liners, the bags can work better and are also thicken the outer shield, offering protection against these external difficulties:

Moisture-Resistant Coatings: Ensure that the substances are neither wet nor injured in places with a lot of moisture.

UV-Stabilized Coatings: They help to extend the lifespan of both the bags and the packed things by keeping them away from the sun rays for a long time.

Barrier Liners: A minimal flow of gas and the suitable quantity of each substance provide resistance of the liners towards chemical, gas pollution and odors, therefore being applicable when the chemicals are so harmful to health.

6. Technological Integration

Bulk Bags is an area where the integration of technology has been a welcome change. For example, some producers embed the RFID (Radio-Frequency Identification) tags in their bags. The tags, in turn, enable companies to handle and control the inventory smoothly and easily by giving location and status information in real-time.

7. Lightweight and Foldable Designs

Today, the innovation behind modern PP-Woven Bags and Big Bags has made them lighter, yet stronger. This eliminates the high cost of transportation and makes it easier to handle the bags. What's more, the foldable designs make sure that the bags take up a minimal area which helps to optimize the storage.

8. Focus on Cost-Effectiveness

Manufacturers are making FIBC Big Bags more affordable while striving for the improvement of their functionalities. New technologies and better, faster, and cheaper production processes like automated weaving and coating have reduced the cost of manufacturing. These newly-acquired savings are passed on to consumers making high-quality Bulk Bags more accessible to businesses of all sizes.

9. Growing Role of Polypropylene Bag Manufacturers

Sought-after polypropylene bags, leaders in manufacturing, are pioneering the industry by resorting to the use of advanced techniques and sustainable methods. They are channeling significant resources into R&D with a view to making bags that can be more durable, lighter, and more flexible.

10. Multi-Functionality Across Industries

Big Bag manufacturers have become very flexible, and they’re now coming up with bags that can do many different things which also act as the environmentally friendly options for transportation and storage.

Bags that can function as ventilated and moisture-resistant containers for various purposes.

Convertible bags that can be adopted as flatbeds on simple unloading of content.

Conclusion

The progress in Big Bags has brought about essential tools in various sectors. From reinforced stamina and safety characteristics to nature-friendly and technical innovations, these bags have been produced to keep pace with the increasing needs of companies globally.

0 notes

Text

1 note

·

View note

Text

Ensuring Safety with Food Grade FIBC: The Key to Safe Bulk Food Handling

What is Food Grade FIBC?

Food grade Flexible Intermediate Bulk Containers (FIBC) are specialized bulk bags designed to meet stringent safety and hygiene standards for transporting food products. Made from materials that comply with food safety regulations, these FIBCs ensure that the contents remain uncontaminated and safe for consumption throughout the supply chain.

Why Food Grade FIBC Matters

The primary role of food grade FIBC is to prevent contamination of food products. These bags are manufactured from materials that do not leach harmful substances into the contents and are subjected to rigorous testing to ensure compliance with food safety standards. The bags are also designed to be resistant to moisture, pests, and other contaminants that could affect the quality of the food.

Key Features of Food Grade FIBC

Material Compliance: Food grade FIBC are made from materials approved by regulatory agencies, ensuring they are safe for direct contact with food.

Hygienic Design: The bags are designed to be easily cleanable and free from any residues or contaminants that could affect food quality.

Durability: These FIBCs are constructed to withstand the rigors of transportation and handling, preventing leaks and ensuring the safety of the food during transit.

Applications of Food Grade FIBC

Food grade FIBC are used in a variety of applications within the food industry. They are commonly used for transporting bulk grains, flour, sugar, and other dry food products. Additionally, they are utilized for handling ingredients and additives in food processing facilities. The versatility of food grade FIBC makes them an essential component of the food supply chain, ensuring that products reach consumers in a safe and uncontaminated state.

Ensuring Compliance and Safety

When selecting food grade FIBC, it is crucial to ensure that they meet relevant food safety standards and regulations. Manufacturers should provide certifications and documentation verifying the safety and suitability of their bags for food handling. Additionally, proper storage and handling of these bags are essential to maintaining their integrity and ensuring the continued safety of the food products they contain.

Food grade FIBC play a vital role in the safe handling and transportation of bulk food products. Their adherence to strict safety standards and their hygienic design make them indispensable in the food industry. By choosing the right food grade FIBC, businesses can ensure that their products remain safe and uncontaminated from the point of production to the consumer's table.

0 notes

Text

Givenchy Fall 2023

14 notes

·

View notes

Text

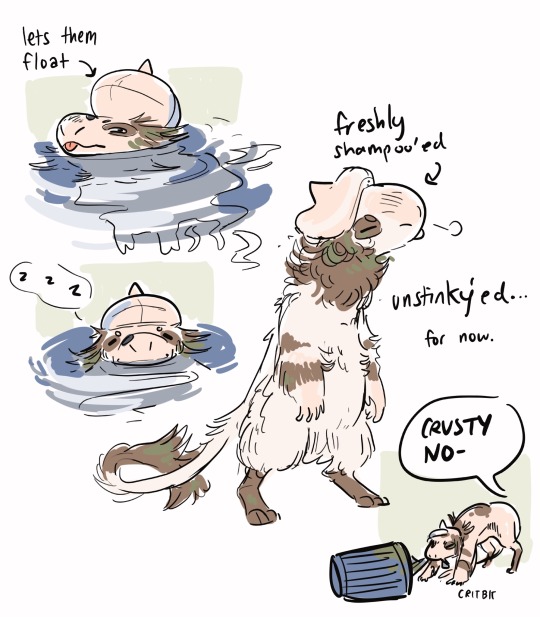

I made another one. Sorry guys.

#pokemon#art#my art#unholy grab bag of guys#smeargle#pokemon oc#smeargle oc#pkmn art#oc art#oc#crusty the smeargle#sweaty the absol#critdraws#they fill me with emotions that i can not describe#fear? revulsion? joy???#anyways crusty can have an airsack as a treat#when it deflates it sounds like a whiney train horn#or a very big bike honk

15K notes

·

View notes